Ahmedabad, Gujarat Nov 21, 2022 (Issuewire.com) - Indian industriss are looking for cost reduction need to meet market demand & looking to Scale business by implementing Lean Practice with India's Leading Lean six sigma consultant - Greendot Management Solutions

The top Indian manufacturing industries started implementing Lean manufacturing principles, which have long been used in other industries, to reduce the time and money it takes to release their products.

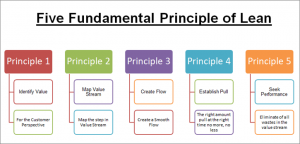

Lean manufacturing is essentially removing non-value-adding activities or waste from the production system.

Indian industriees will only survive if they reduce the cost of operation, and optimize their operating cost

Therefore, it may be necessary to push researchers and practitioners to establish improved approaches which are suitable for the industry. I

t is now widely accepted that Lean Manufacturing practice is of considerable benefit in manufacturing, so there is growing interest in it among companies in the pharmaceutical industry.

A lean manufacturing case study in India top Indian Industries - By greendot management solution

In order to provide an example of how it is possible and convenient to shift attention from effectiveness to efficiency, we now present the case of an industry that is dealing with challenges, and which has reaped large benefits by using targets for manufacturing operations.

The case study concerns the plant of a primary multinational company in the pharmaceutical industry. This plant produces pharmaceutical products in a solid form (pills, tablets, capsules, etc.). The company has about 400 employees and its annual production adds up to about 10 CR units per month sold in the Indian market.

The management has implemented a Lean Management approach, but the primary focus has been on achieving efficiency through improvement activities which are aimed at:

-

Reducing change overtime by implementing SMED practice

-

Deleting non-added value activities Popularly known as NVA

-

Reducing Inventory ( RM, FG, WIP)

Within the general improvement programme, we have focused on a specific project that has been developed in two synergic ways in a pilot production flow:

-

Re-engineering of the production flow

-

Implementing a pull-based production system by implementing kanban,

Both methods have contributed to the following goals:

-

Total Pipeline Lead Time reduction

-

Throughput Time Reduction

-

WIP (Work In Process) reduction

-

Layout re-design

Concerning the latter goal, the major problem was an excessive walkthrough product, which divided production flow into different production areas.

There Is clear cut improvement you can observe by implementing lean practice in Indias Top 10 pharmaceutical company

Before the implementation of Lean Manufacturing in India top 10 pharmaceutical companies

1. Per month production - 10 Cr units in 2 Shift

2. Change overtime for 20 Machine - 300 min average per machine

3. Overtime - 31 lakh

4. Yield - 94.2 %

After Implementing lean Manufacturing practices By greendot management solution Indian top 10 pharmaceutical companies improved, significant profits.

1. Per month production - 10 Cr units in 1 Shift, resulting in A saving of utility cost of around 15 lakh per month

2. Change overtime for 20 Machine - 300 min average per machine, reduced to 180 minutes per machine, increase productivity by 50 %

3. Overtime - overtime of 31 lakh has been reduced to nil amount clear saving of 31 lakh per month.

4. Yield - 94.2 % improved to 96% resulting in a gain of material of 18 lakh per month.

This is how a two-shift production was carried out in one shift. Without having more resources, the company could save costs and be able to meet the market need.

Lean manufacturing practice will be essential for any pharmaceutical industry.

Media Contact

greendot management solution nirav@mygreendot.co.in 982556009 http://www.mygreendot.co.in