Jinhua, Zhejiang Jun 16, 2024 (Issuewire.com) - Zhejiang BW Industry Company (BW Company), a leader in advanced wire solutions, proudly announces the successful application of its PEEK magnet wire in 800V electric vehicles. This groundbreaking innovation sets new standards for the automotive industry, combining exceptional performance with sustainable practices.

At the recent China Electric Vehicle Drive Motor New Technology and New Process Forum, BW Company showcased its latest advancements in high-voltage motor wire solutions. The company highlighted the superior characteristics of PEEK (polyether ether ketone) insulation material, demonstrating why it is particularly suitable for 800V environments, especially in continuous wave winding applications.

Advantages of PEEK Magnet Wire

PEEK magnet wire represents a significant technological leap, offering numerous advantages over traditional magnet wires:

- High-Temperature Resistance: PEEK material can operate at continuous temperatures up to 260°C, making it ideal for high-stress environments.

- Mechanical Strength: PEEK’s strength surpasses that of conventional engineering plastics and even some metals, ensuring durability and reliability.

- Chemical Resistance: PEEK is highly resistant to acids, bases, and solvents, ensuring long life and stability under various conditions.

- Electrical Insulation: PEEK’s excellent insulation properties help maintain the efficiency and safety of high-voltage motors.

- Sustainability: PEEK is recyclable, aligning with global trends towards environmentally friendly and sustainable manufacturing.

Technical Parameters and Performance

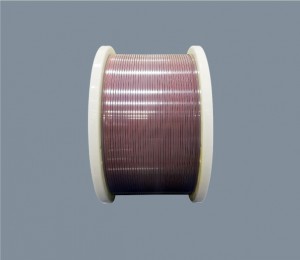

BW Company has successfully overcome the challenge of combining inert PEEK material with copper conductors. Its proprietary technology ensures uniform and consistent PEEK insulation, with thicknesses ranging from 60 to 300 microns. The minimum R angle for PEEK magnet wire is 0.3 millimeters, ensuring high stability and consistency in production, essential for automotive applications.

Key Comparisons of High-Voltage Magnet Wire

BDV and PDIV

PEEK magnet wire significantly outperforms traditional magnet wire in terms of BDV (Breakdown Voltage) and PDIV (Partial Discharge Inception Voltage). PEEK magnet wire achieves BDV of over 10kV, compared to the typical 6kV for conventional wires. In PDIV tests, PEEK magnet wire shows superior corona resistance, effectively preventing partial discharge and extending motor lifespan.

Eccentricity and Flexibility Testing

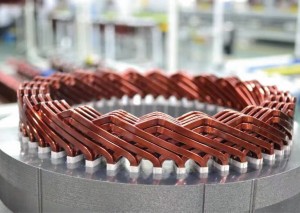

PEEK magnet wire also excels in eccentricity and flexibility tests. BW Company’s manufacturing process ensures that the eccentricity of PEEK magnet wire is controlled within 5%, far superior to the industry average. This precise manufacturing ensures excellent flexibility and consistency of PEEK magnet wire in high-stress and complex geometric motor windings.

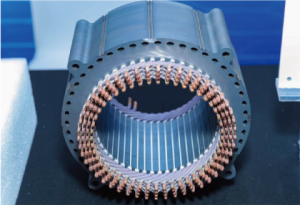

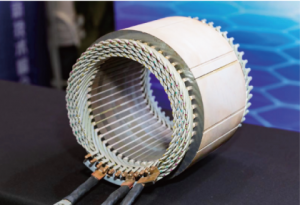

Production Process and Continuous Wave Winding

BW Company employs advanced manufacturing processes to ensure high consistency in the thickness and quality of PEEK magnet wire. The application of continuous wave winding technology makes PEEK magnet wire more efficient and reliable in high-speed motors. Rigorous flexibility and PDIV testing ensure that BW Company’s PEEK magnet wire maintains stable performance under extreme conditions.

Practical Application and Impact

Since mass production began in November 2023, BW Company’s PEEK magnet wire has been applied in a range of electric vehicles, including a high-performance sports SUV manufactured in Wuhan. The application of PEEK wire in these vehicles has shown outstanding performance, surpassing industry standards in electrical insulation and mechanical strength.

Challenges Before Using PEEK Magnet Wire

Before adopting PEEK magnet wire, the electric vehicle industry faced multiple challenges with traditional magnet wire under high-voltage conditions:

- Severe Motor Heating: Traditional magnet wire’s insufficient insulation under high voltage and current conditions led to significant heat generation, causing motors to overheat or even burn out.

- Shorter Driving Range: Due to motor heating issues, the efficiency of electric vehicles was reduced, leading to faster battery depletion and shorter driving ranges.

- High Maintenance Costs: Frequent motor overheating and insulation failures increased the frequency of repairs and part replacements, significantly raising maintenance costs.

- Unstable Performance: Traditional magnet wire’s instability under high temperatures and voltages resulted in poor reliability of electric vehicles under extreme conditions.

BW Company’s PEEK magnet wire addresses these challenges, providing superior performance and reliability while offering cost-effective solutions in the long run.

About Zhejiang BW Industry Company

Established in 2008, Zhejiang BW Industry Company has been dedicated to developing and producing high-quality flat magnet wire for 15 years. Initially focusing on the consumer electronics sector, the company has now expanded its expertise to meet the high demands of the automotive industry. BW Company’s commitment to innovation and excellence continues to drive its success, making it a trusted supplier of advanced wire solutions.

Media Contact

ZHEJIANG BW INDUSTRY CO.,TD sales@peekmaterials.com +86-3868966491 NO 77,YONGXING WEST ROAD,YOUBUTOWN, LANXI CITY,ZHEJIANG PROVINCE,CHINA https://peekmaterials.com