Albany, Oregon Sep 3, 2019 (Issuewire.com) - MEI has delivered a dual robot, fully automatic Evolution wet process system to a repeat customer in the US Midwest.

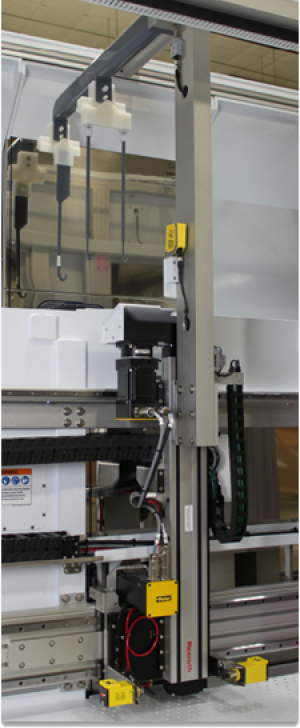

MEI’s fully automated Evolution wet processing system was selected in part due to our highly flexible IDX software scheduler and multi-robot automation package. IDX incorporates a sophisticated scheduler that enables simultaneous processing of multiple production lots with separate recipes for each. The MEI Evolution design is well suited for high volume manufacturing applications. This particular critical clean application required recipe configurable, in-tank agitation by the process robot. In addition, agitation assemblies had to be incorporated in one of the strategic rinse tanks to provide rapid quenching of the etch process for consistent device performance. The Evolution’s elliptical agitation movement increases the speed at which the sidewall polymer removal occurs and provides more consistent chemical interaction with each wafer. MEI’s IDX scheduler maximizes each robot’s utilization and keeps production moving for optimal throughput. To ensure the highest quality dry this Evolution system incorporated MEI’s Genesis XTM Marangoni dryer.

Sidewall polymer, FeOL cleans often require high volume and production space is very limited. MEI’s dual robot design and sophisticated scheduling software solve this problem by providing the ability to produce more wafers per sq/ft of space.

MEI’s IDX FlexViewTM data recording software provides focused tracking of all monitored process variables for each lot ID that is processed. Using FlexViewTM, MEI customers can quickly confirm that all process variables were within specified limits while processing occurred. In addition, IDX feeds this data back to the user's systems through our SECS/GEM host software.

Our goal is to provide our customers with the best possible process control by using state of the art technology to ensure maximum uptime and reliability. Through a combination of process experience, software sophistication, and robust design, MEI provides superior wet process systems for a wide variety of applications.

Media Contact

MEI Wet Processing Scott.Tice@meillc.com (541) 917-3626 3838 Western Way NE https://www.meillc.com